Industrial Pump Service Plan

Precision Care for Pumping

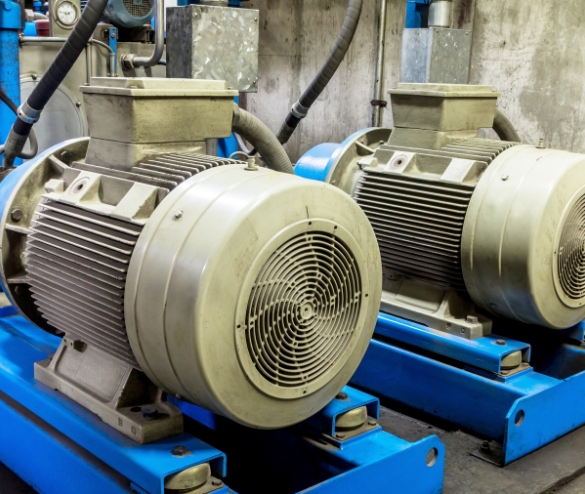

Preventive imaging, flow testing, and vibration analysis reveal seal wear, cavitation, or misalignment before breakdowns occur. Technicians review amp draw and meg readings on coupled motors to verify insulation and loading, then record findings for plant reports.

Corrective work includes bearing change-out, impeller balancing, and alignment to factory tolerances. Lubrication schedules and contamination control keep pumps reliable in harsh duty, reducing downtime while extending equipment life cycle.

Pump Service Process Guide

Ensuring Reliable Pump Performance

Routine vibration, flow, and thermal surveys uncover cavitation, seal wear, and bearing distress before discharge pressure drops. Technicians record amp draw, megohm values, and temperature trends to confirm motor-pump alignment and insulation health.

Corrective work covers impeller trim, bearing change-out, seal upgrades, and laser alignment. Lubrication is matched to OEM intervals, and filtered flushing removes contaminants. Final vibration checks and flow tests confirm safe operation and longer pump life under heavy cycles.

Detect Wear Early

Address Found Failures

Program For Long-Term Health

Pump Care Advantages

Supports OEM Range

Service covers Siemens, WEG, Sulzer, and more brands with tailored inspection routines.

Diagnostic Rigor

Thermal imaging, meg tests, and flow checks verify pumps fully meet strict factory criteria.

Longer Pump Life

Preventive schedules, seal upgrades, and lubrication control extend life and reduce cost.

Certified Expertise

Certified advisors interpret vibration and flow data to maintain safety and audit compliance.

Quality Pledge

Timely Help Anytime Needed

Pump service logs capture vibration patterns, thermal images, and seal health. Follow-up flow and pressure checks verify performance and provide documented assurance, cutting downtime risk for critical plant pumps.