Why SJM Advising

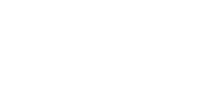

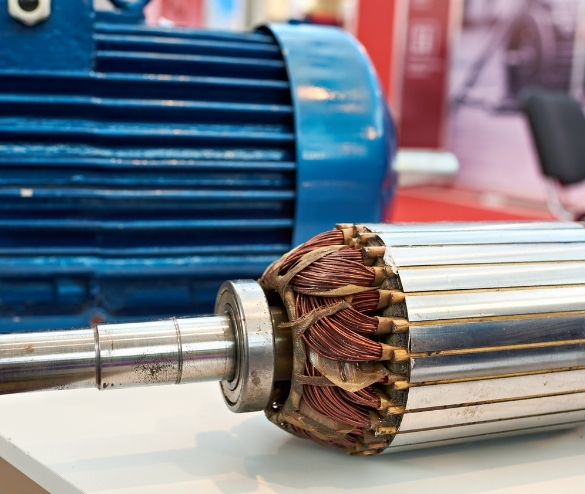

With over 25 years in the rotating apparatus field, SJM Advising delivers expert electric motor, pump, gearbox, and blower repair. Our preventative maintenance plans reduce costly downtime, while detailed inspections—thermal imaging, vibration analysis, and meg checks—help detect failures early and extend equipment life.

We service both AC and DC motors from leading manufacturers. Programs are tailored for 1 to 200 units, ranging from 5HP to 500HP. From electrical testing to contamination assessments, our mission is to enhance reliability and safety for every client through precise diagnostics and proven methods.

The SJM Advising Commitment

We deliver expert repair and analysis for motors, pumps, blowers, and gearboxes. Whether on-site or in-shop, every inspection targets performance, safety, and extended lifespan. From meg checks to thermal scans, we offer diagnostics that identify issues early—reducing downtime, preventing failures, and saving operating costs.

Rotating Equipment Service Plans

Our team provides repair and inspection support for AC/DC motors, pumps, gearboxes, and blowers. Inspections identify issues early to improve system reliability, reduce downtime, and extend mechanical performance.

Extend The Lifespan Of Your Motor System

Prevent Costly Failures

Motor Service Range

We support 5HP to 500HP units with trusted field checks.

System Testing

We run amps, ohms, meg tests, and thermal diagnostics.

Rotating Balance

Vibration review detects misalignment and wear early.

Certified Work

All units cleared after final inspection and testing.

Preventative Service Plans

Built To Detect Issues Before Downtime Hits

Preventative diagnostics help identify early faults in motors, gearboxes, and pumps. Our field process includes meg checks, insulation review, vibration analysis, and thermal imaging—offering data to reduce failure risk and extend the life of rotating apparatus systems. Each inspection is tailored to operating demands.

What Clients Say

SJM quickly identified bearing wear and helped restore output. Their analysis saved our team hours of downtime. Service was precise, and communication was excellent throughout inspection.

Jason Wheeler

Facilities Lead

Thermal and meg testing helped avoid an unexpected outage. The team provided insight into load imbalance and kept our systems operating safely. Definitely our first call for repairs.

Ops Supervisor

Reliable With Fast Results

We had recurring issues with motor startup. They traced the cause, rebuilt it, and got us running quickly. The inspection scope covered every detail, and their field techs were on point.

Maintenance Mgr