Gearbox Overhaul Support Plan

Precision Care for Gearboxes

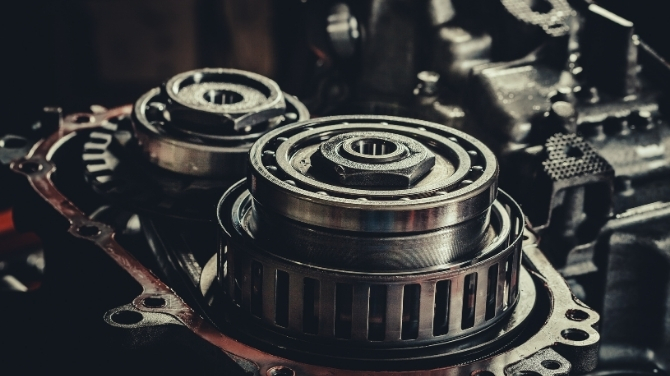

Our specialists evaluate gearbox condition through vibration signatures, thermal imagery, and oil contamination checks, identifying bearing distress, gear tooth wear, and misalignment long before shutdowns occur. Results guide on-site recommendations and parts sourcing.

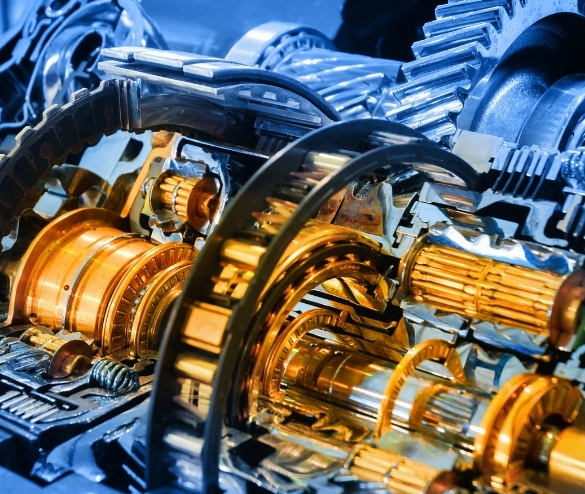

Preventative service plans include amp and megohm testing, brush and seal replacement, precision shimming, and calibrated lubrication intervals. These measures minimise unplanned downtime, meet manufacturer tolerances, and extend gearbox life across demanding heavy global cycles.

Gearbox Support Procedure

Ensuring Reliable Gearbox Function

Technicians begin with vibration signatures, oil debris checks, and thermal scans to detect imbalance, gear wear, or lubrication loss before production stops. Amp and megohm readings confirm electrical demand and insulation integrity in integral motor-gear systems.

After diagnosis, specialists set alignment, replace bearings, and restore proper backlash. Scheduled lubrication and contamination control reduce heat and extend component life. Follow-up tests verify load balance and keep the drive running within tolerance.

Before Faults Surface

After Damage Located

Plan Long-Term Health

Gearbox Support Plan

Covers OEM Range

Service spans ABB, SEW-EURODRIVE, Rexnord, and other listed brands for tailored upkeep.

Testing Quality

Amp, megohm, and thermal diagnostics meet factory criteria to confirm optimal condition.

Extended Lifespan

Preventive programs cut downtime and extend gear tooth life through aligned lubrication.

Certified Experts

Field advisors apply vibration trends and bearing data to meet safety and audit demands.

Service Pledge

Support Whenever You Need

We back every gearbox overhaul with certified diagnostics and post-repair testing. Vibration, thermal, and contamination reports are documented so operations teams prove reliability and lower downtime costs greatly.